Specialist Testing:

Tensile, Compression, and Proof Testing Services

On site, and Off site proof load and SWL Testing Services

On site, and Off site proof load and SWL Testing Services

The purpose of Mechanical Testing is to determine the strength of a material or piece of equipment. Plant and Safety are national experts for a wide range of specialist testing services including Mechanical Tensile and Compression Testing, Proof Load Testing, and Overload Testing. Our highly experienced and qualified team of engineers and technical support teams are able to provide advice, support, and guidance on how to comply with mechanical testing requirements in accordance with British, European, International, and Bespoke Standards.

Plant and Safety offer Mechanical Tensile Testing Services to verify the strength of a material or piece of equipment. Tensile Testing is a common testing method used to establish how strong a material is and also how much it can be stretched before it breaks, which is also known as ‘Destructive Testing’.

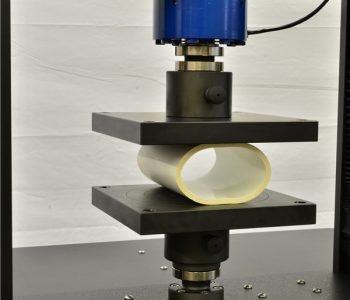

Plant and Safety offer Mechanical Compressing Testing Services to verify the strength of a material or piece of equipment. Compression Testing is a common testing method used to establish the compressive force or resistance of a material and the ability of the material to recover after the specified compressive force is applied and held over a defined period of time.

Plant and Safety are able to carry out both On Site and Off Site Mechanical Testing Services. Our testing facility located Staffordshire contains 50 Tonne horizontal and vertical test machines calibrated in accordance with ISO 7500:1 2004. Where possible, hydraulics are utilised for higher tonnage tests to ensure the safety of our engineers, whilst maintaining accuracy and control during the test procedure.

Plant and Safety offer Proof Load Testing and Overload Testing Services. Load Testing involves applying a load to a structure, material, or piece of equipment to verify its strength. A proof load test is usually expressed as a percentage of the working load limit (WLL) or safe working load (SWL) that the equipment is designed to withstand.

Proof Load Testing of lifting equipment is required to ensure that items of lifting equipment can perform to the required British or European standard, and in accordance with the designed safe working load (SWL) or working load limit (WLL) calculated by the original equipment manufacturer (OEM) during the design and manufacturing process.

Typically, Lifting Equipment has to be tested in accordance with LOLER 1998 and the relevant British or European Standard for the following reasons:

• After the equipment has been manufactured, Installed, Repaired, Modified or Refurbished

Following an incident;

• Periodic testing may be specified in some British or European Standards (i.e. BS7121 for Lorry Loader and Mobile Cranes)

• A competent person may also require a proof load test is carried out during a Thorough Examination process to determine whether a piece of lifting equipment is safe to use.

The exact requirements of a Proof Load Test or Overload Test can vary depending on the standards, equipment, and individual requirements of the customer or original equipment manufacturer (OEM).

Lifting equipment is designed and manufactured in accordance with a British, European, International, or Manufacturer (OEM) Standard. Both the relevant Standard and LOLER requires lifting equipment to be tested to verify and certify the Working Load Limit (WLL) or Safe Working Load (SWL). All lifting equipment has to be tested at some point during the design, manufacturing, installation process, or for any other reason given by a competent person or to ensure compliance with LOLER 1998.

The list below includes some, but not all, lifting equipment which requires a proof load test;

> Chain Block Proof Load Testing

> Eyebolts and Lifting Points Proof Load Testing

> Lifting Chains Proof Load Testing

> Mobile Crane Proof Load Testing

> Excavators Proof Load Testing

> Overhead Gantry Crane Proof Load Testing

> Gantry Frame Proof Load Testing

> Lift Shaft Beam Proof Load Testing

> Lifting Chains Proof Load Testing

> Jacks, Toe JacksProof Load Testing

> Jib Cranes Proof Load Testing

> Lifting Equipment Proof Load Testing

> Vehicle lifts Proof Load Testing

> Runway Beam Proof Load Testing

> Eyebolts and Lifting Points Proof Load Testing

> Mobile Crane Proof Load Testing

> Excavators Proof Load Testing

> Lift Shaft Beam Proof Load Testing

> Runway Beam Proof Load Testing

> Forklift Truck Proof Load Testing

> Hoists Proof Load Testing

> Telescopic Handler Proof Load Testing

> Lifting tackle Proof Load Testing

> Webbing Slings Proof Load Testing

> Lorry loaders Proof Load Testing

> Winch Proof Load Testing

*We may contact you occasionally with exclusive offers, promotional discounts, and company updates that may be of interest to you. By ticking the box above, you consent to Plant and Safety LTD storing and processing your personal data. To learn more about how to unsubscribe and how we protect and respect your privacy, please see our updated Privacy Notice.

How can we help?

To learn more or if you have any questions, please feel free to call or email us. You can also request a call back using our online form.

T: 0330 113 7920

E: sales@plantandsafety.co.uk

Useful Links