LOLER Inspection Testing and

Thorough Examination Services

National LOLER inspections and thorough examinations to keep your lifting equipment compliant, safe, and certified.

National LOLER inspections and thorough examinations to keep your lifting equipment compliant, safe, and certified.

Plant and Safety Limited are national providers for LOLER Inspection, LOLER Testing, LOLER Thorough Examination, and LOLER Certification services. Our Lifting Equipment Inspection (LOLER Inspection) services keep your company, and your lifting equipment compliant, ensuring that your employees are able to work safely and effectively. A Lifting Equipment Inspection is required in accordance with LOLER 1998.

Our national team of highly qualified and experienced engineers are able to provide engineering inspection, testing, and certification services on all types of equipment which require a thorough examination under LOLER 1998, PUWER 1998, WAHR 2005, PSSR 2000, and COSHH 2002. This includes Lifting Equipment and Accessories, Work Equipment, Mobile Plant Equipment, Access Equipment, Pressure Systems, Local Exhaust Ventilation, Passenger and Goods Lifts, and Industrial Doors.

Keeping your lifting equipment compliant can be a challenge, which is why our inspection database automatically plans the next due dates for each inspection, allowing us to notify our customers in advance when their lifting equipment needs to be inspected and certified again.

Speak to one of our inspection specialists about your compliance requirements.

View All Inspection Services

The Lifting Operations and Lifting Equipment Regulations 1998 (often abbreviated to LOLER) place duties on people and companies who own, operate or have control over lifting equipment.

This includes all businesses and organisations whose employees use lifting equipment, whether owned by them or not. In most cases, lifting equipment is also work equipment so the Provision and Use of Work Equipment Regulations (PUWER) will also apply (including inspection and maintenance requirements). All lifting operations involving lifting equipment must be properly planned by a competent person, appropriately supervised and carried out in a safe manner.

LOLER also requires that all equipment used for lifting is fit for purpose, appropriate for the task, suitably marked and subject to statutory periodic ‘thorough examination’. This can also be referred to as a LOLER Inspection.

Records must be kept of all thorough examinations and any defects found must be reported to both the person responsible for the equipment and the relevant enforcing authority.

The Lifting Operations and Lifting Equipment Regulations 1998 (often abbreviated to LOLER) place duties on people and companies who own, operate or have control over lifting equipment.

The Lifting Operations and Lifting Equipment Regulations 1998 (often abbreviated to LOLER) place duties on people and companies who own, operate or have control over lifting equipment.

In accordance with the Health and Safety at Work Act 1974 (HASAWA), an employer has the legal responsibility to provide a safe working environment. LOLER 1998 falls under the HASAWA 1974, and place duties on people and companies who own, operate or have control over lifting equipment.

This includes all businesses and organisations whose employees use lifting equipment, whether owned by them or not. In most cases, lifting equipment is also classed as work equipment so the Provision and Use of Work Equipment Regulations 1998 (PUWER) will also apply (including inspection and maintenance requirements).

All lifting operations involving lifting equipment must be properly planned by a competent person, appropriately supervised and carried out in a safe manner.

LOLER also requires that all equipment used for lifting is fit for purpose, appropriate for the task, suitably marked and subject to statutory periodic ‘thorough examination’.

Records must be kept of all thorough examinations and any defects found must be reported to both the person responsible for the equipment and the relevant enforcing authority.

Lifting equipment is any work equipment for lifting and lowering loads, and includes any accessories used in doing so (such as attachments to support, fix or anchor the equipment).

Examples of lifting equipment include:

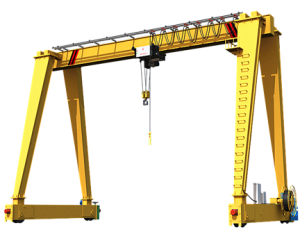

• overhead cranes and their supporting runways

patient hoists

• motor vehicle lifts

• vehicle tail lifts and cranes fitted to vehicles

• a building cleaning cradle and its suspension equipment

• goods and passenger lifts

• telehandlers and fork lifts

• lifting accessories

Lifting accessories are pieces of equipment that are used to attach the load to lifting equipment, providing a link between the two. Any lifting accessories used between lifting equipment and the load may need to be taken into account in determining the overall weight of the load.

Examples of lifting accessories include:

• fibre or rope slings

• chains (single or multiple leg)

• hooks

• eyebolts

• spreader beams

• magnetic (PDF) – Portable Document Format and vacuum devices

LOLER 1998 covers all Lifting Equipment and Lifting Accessories, including but not limited to:

• Fibre, Wire Rope, and Chain Slings

• Shackles, Eyebolts, and Hooks

• Chain Blocks, Pull Lifts, and Lever Hoists

• Manual and Electric Hoists

• Overhead Electric and Manual Gantry Cranes

• Runway Beams, Spreader Beams, Lift shaft Beams, and Lifting Frames

• Passenger and Goods Lifts

• Vehicle Tail Lifts

• Forklift Trucks and Telescopic Handlers

• Excavators

• Vehicle Ramps

• Hiab Cranes

• Swing Jibs and Mobile Gantry Frames

• Vacuum and Magnetic Lifters

This is a systematic and detailed examination of the equipment and safety-critical parts, carried out at specified intervals by a competent person who must then complete a written report. This report must contain the information required by LOLER Schedule 1, including; the examination date, the date when the next thorough examination is due, any defects found which are (or could potentially become) a danger to people

Where serious defects are identified, the competent person carrying out the examination must immediately report this verbally to the dutyholder. This should then be followed by the written report, a copy of which must also be sent to the relevant enforcing authority.

Unless there is an ‘examination scheme’ specifying other intervals, thorough examinations should be conducted every:

• 6 months, for lifting equipment and any associated accessories used to lift people

• 6 months, for all lifting accessories

• 12 months, for all other lifting equipment

The term ‘competent person’ is not defined in law but the LOLER Approved Code of Practice and guidance (paragraph 294 on competent persons) states that:

‘You should ensure that the person carrying out a thorough examination has such appropriate practical and theoretical knowledge and experience of the lifting equipment to be thoroughly examined as will enable them to detect defects or weaknesses and to assess their importance in relation to the safety and continued use of the lifting equipment.’

Lifting Equipment is any type of work equipment used for lifting and lowering loads, and includes accessories used in doing so (such as attachments to support, fix, or anchor the equipment). Examples of Lifting Equipment Includes, but is not limited to: Fibre, Wire Rope, and Chain Slings, Shackles, Eyebolts, and Hooks, Chain Blocks, Pull Lifts, and Lever Hoists, Manual and Electric Hoists, Overhead Electric and Manual Gantry Cranes, Runway Beams, Spreader Beams, Lift shaft Beams, and Lifting Frames, Passenger and Goods Lifts, Vehicle Tail Lifts, Forklift Trucks and Telescopic Handlers, Excavators, Vehicle Ramps.

In accordance with the requirements defined under the LOLER 1998 Regulations, a competent person should carry out a LOLER Inspection and Thorough Examination of Lifting Equipment and Accessories every:

› 6 Months for Lifting Accessories

› 6 Months for Lifting Equipment and Accessories associated with lifting people

› 12 Months for All Other Lifting Equipment

› Any other frequency defined by the written scheme of examination

LOLER Inspection, LOLER Inspection, Lifting Equipment Thorough Examination, LOLER TesER Testing, LOLER Testing LOLER Testing, LOLER Inspection, LOLER Inspection, Lifting Equipment Thorough Examination, LOLER Testing, LOLER Testing, LOLER Testing LOLER Testing, Lifting Equipment Inspection, Lifting Equipment Inspection, LOLER Inspection, LOLER Inspection

For a fast quote or to schedule your next LOLER Thorough Examination & Test.

We provide nationwide LOLER inspection services with reliable turnaround times and expert guidance.

*We may contact you occasionally with exclusive offers, promotional discounts, and company updates that may be of interest to you. By ticking the box above, you consent to Plant and Safety LTD storing and processing your personal data. To learn more about how to unsubscribe and how we protect and respect your privacy, please see our updated Privacy Notice.

Still unsure?

How can we help?

To learn more or if you have any questions, please feel free to call or email us. You can also request a call back using our online form.

T: 0330 113 7920

E: sales@plantandsafety.co.uk

Useful Links