Home » Local Exhaust Ventilation (LEV) » How Often Should LEV Systems Be Thoroughly Examined and Tested?

Local Exhaust Ventilation (LEV) is one of the most effective ways to control airborne contaminants in the workplace. Under the Control of Substances Hazardous to Health (COSHH) Regulations, employers have a legal duty to maintain their LEV systems and ensure they remain effective.

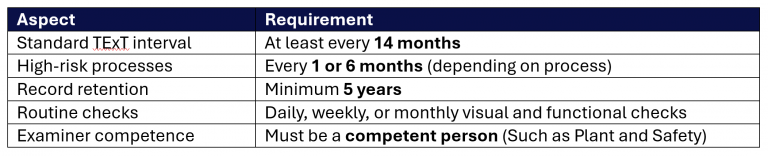

LEV Thorough Examination and Test: Minimum Testing Interval: Every 14 Months

A key part of this duty is the Thorough Examination and Test (TExT) a statutory check to confirm that the system is controlling exposure as intended.

Explore how LEV Thorough Examination and Test supports your COSHH duties →

The Legal Requirement Under COSHH

According to COSHH Regulation 9 and guidance in HSG258, Controlling airborne contaminants at work:

- Every LEV system must be thoroughly examined and tested at least once every 14 months.

- Records of each test must be kept for a minimum of five years

This interval is the maximum period allowed by law, meaning systems can and should be examined more frequently if risk assessment or system performance indicates a need.

View the full COSHH Regulations on legislation.gov.uk →

SAFETY REGULATIONS

Got questions about COSHH or LEV thorough examination? Visit our FAQ or simply fill out the form below and we’ll get back to you.

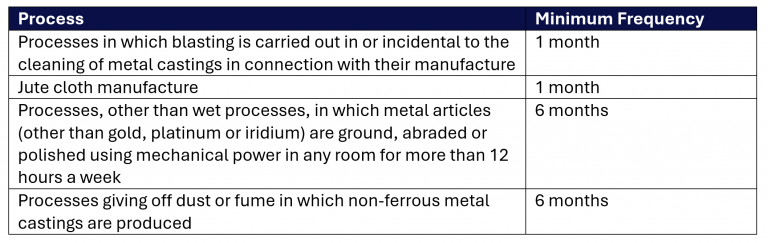

When More Frequent LEV inspection Is Needed

COSHH Schedule 4 identifies specific high-risk processes where LEV systems must be tested more often:

*Table reference HSE guide, Local Exhaust Ventilation – Table 18 – page 85

Routine Maintenance and User Checks Before LEV Thorough Examination and Test

HSG258 also recommends routine user checks to ensure the system is working correctly between statutory LEV Thorough Examination and Test, such as:

- Visual inspections of hoods, ducts, and filters

- Checking airflow indicators or gauges

- Listening for unusual noises or signs of damage

These should be carried out daily, weekly, or monthly as appropriate and recorded in the LEV logbook.

Get your system ready for LEV Thorough Examination and Test with this LEV inspection checklist →

Competence for Examiners for the LEV Thorough Examination and Test

The HSE makes it clear that a competent person must carry out the LEV Thorough Examination and Test. Competence means having the right combination of knowledge, experience, and skills to accurately assess the LEV system’s performance.

Examiners should refer to:

- The original commissioning data or design specifications

- Previous test results

- Manufacturer’s instructions

This ensures the system continues to meet its intended control performance.

Why Testing and Records Matter for LEV Thorough Examination and Test

Failing to carry out timely LEV inspection risks:

- Loss of effective exposure control

- Increased risk of occupational ill health

- Enforcement action for non-compliance with COSHH

Regular LEV Thorough Examination and Test, combined with ongoing maintenance and daily checks, are the only way to ensure that your LEV system protects workers and stays compliant.

WHAT WE OFFER

How Plant & Safety Can Help

At Plant and Safety, we provide professional LEV Testing services carried out by BOHS P601 qualified engineers. We help ensure your systems are compliant, efficient, and fully documented.

Some of the things we can offer:

› Comprehensive LEV report and clear compliance guidance

› Secure inspection database with automated re-test reminders

› COSHH risk assessments

› Highly qualified, experienced engineers (BOHS P601)

› Operator training

All of our reports meet HSE and HSG258 standards.

How can we help?

To learn more or if you have any questions, please feel free to call or email us. You can also request a call back using our online form.

T: 0330 113 7920

E: sales@plantandsafety.co.uk

Useful Links