Non-Destructive Testing

(NDT) Services

Destructive Testing (NDT) on a wide variety equipment and materials.

Destructive Testing (NDT) on a wide variety equipment and materials.

Our national team of highly qualified and experienced engineers are able to provide Non Destructive Testing (NDT) on a wide variety equipment and materials. Our NDT methods offered include Magnetic Particle Inspection (MPI) NDT, Ultrasonic NDT, and Dye Penetrant NDT.

By definition, Non Destructive Testing is the testing of materials for surface or internal flaws or metallurgical condition, without interfering with the integrity of the material or suitability for service. The technique can be applied on a sampling basis for individual investigation or may be used for complete checking of material in a production quality system.

Destructive Testing destroys or changes the material in some way such that even if it passes the test, it is no longer fit for services. Examples might be tensile and compression testing. Non Destructive Testing (NDT) does not destroy or change the material so that it remains still fit for service if it passes the test.

Plant and Safety Limited are national providers in providing Engineering Testing, Inspection, and Certification services in order to keep your company, and your equipment compliant, ensuring that your employees are able to work safely and effectively.

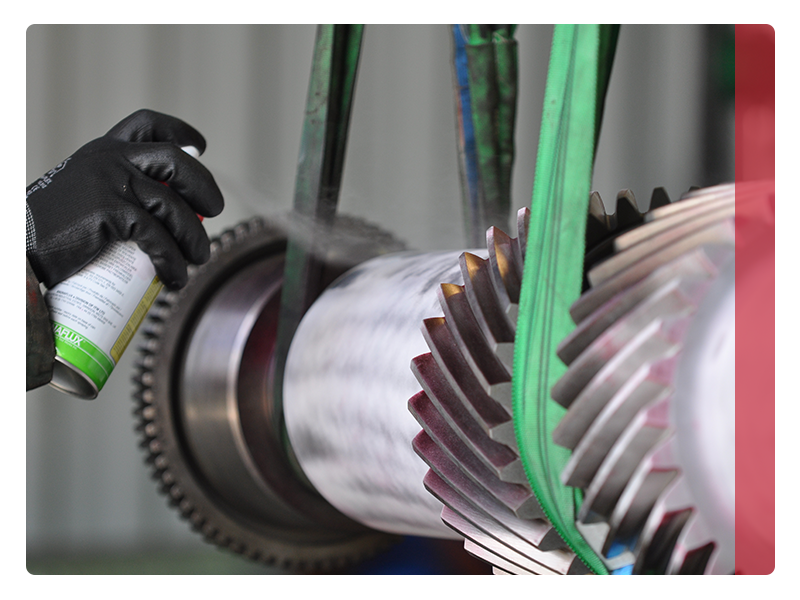

MPI is also known as Magnetic Particle Inspection. This method of Non Destructive Testing is used to detect surface and sub-surface discontinuities in ferromagnetic materials.

MPI can typically be used for the examination of welds, castings, forgings, and final machined components on new or existing equipment and structures. MPI NDT uses finely divided ferromagnetic particles to identify the location, size, and shape of the discontinuity.

Dye Penetrant NDT is used to detect surface breaking defects in both ferrous and non-ferrous materials. Dye Penetrant testing examines the surface of an item for surface breaking defects, such as cracks. Liquid penetrant is applied to the surface and left to soak, being drawn into any cracks by capillary action. Excess Dye Penetrant is then removed and a developer is applied to draw out the penetrant from cracks, which allows a visual inspection of any defects to be carried out.

Ultrasonic testing uses sound waves to identify and evaluate internal flaws. Typically used to assess weld penetration, fusion of boiler welds and any welded components in areas where visual inspection is not possible. used for complete checking of material in a production quality system.

*We may contact you occasionally with exclusive offers, promotional discounts, and company updates that may be of interest to you. By ticking the box above, you consent to Plant and Safety LTD storing and processing your personal data. To learn more about how to unsubscribe and how we protect and respect your privacy, please see our updated Privacy Notice.

How can we help?

To learn more or if you have any questions, please feel free to call or email us. You can also request a call back using our online form.

T: 0330 113 7920

E: sales@plantandsafety.co.uk

Useful Links